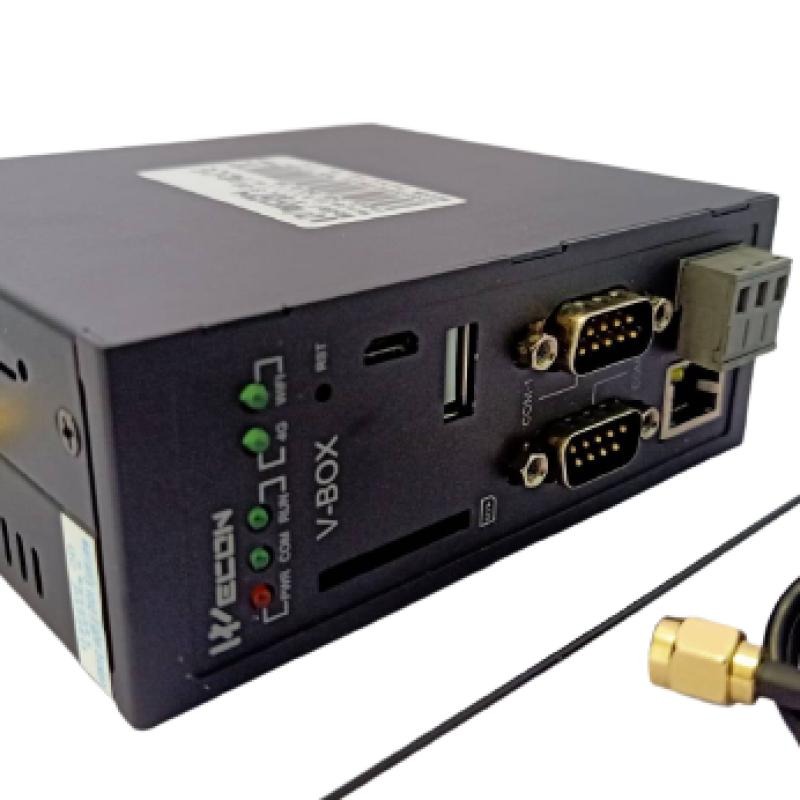

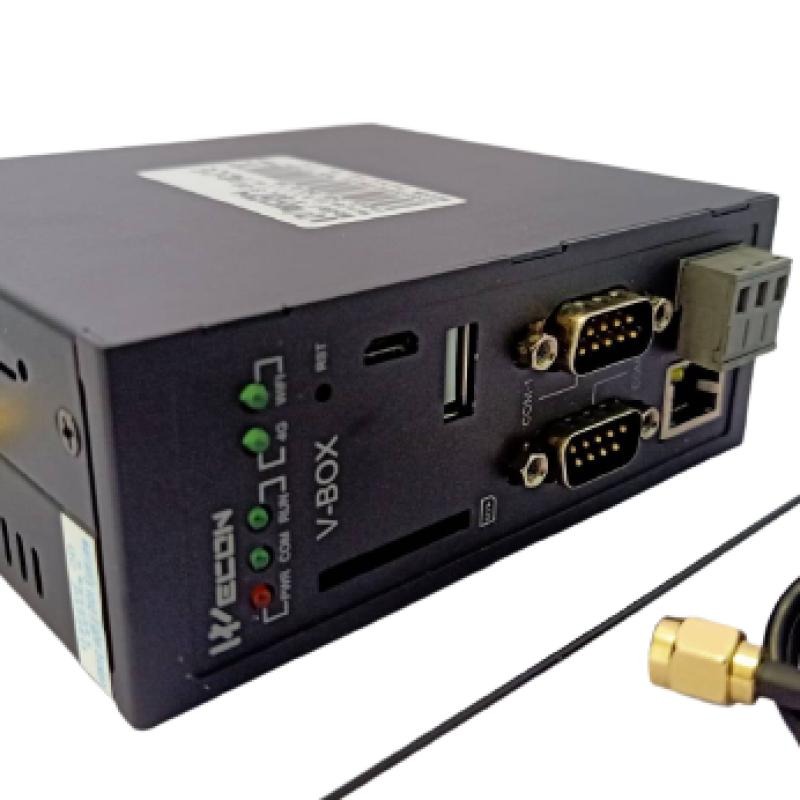

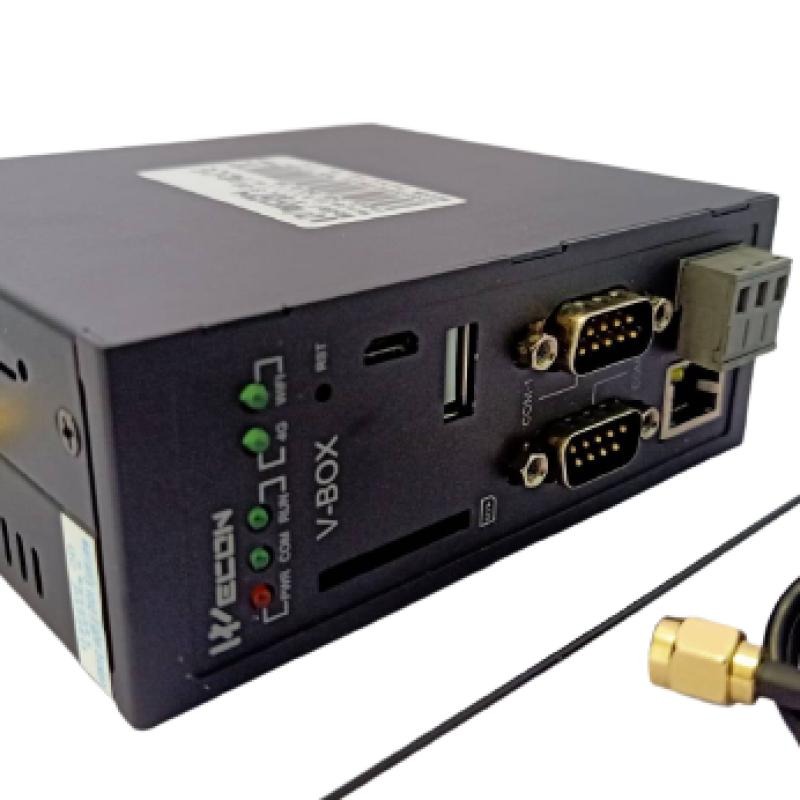

wecon dealer in coimbatore wecon dealer in hosur wecon dealer in tirupur wecon dealers in coimbatore wecon dealers in hosur wecon dealers in tirupur The WECON VD2F series consists of compact, pulse-type servo drives designed for general-purpose industrial positioning applications. They are part of the VD2 SA series of servo drives, known for being affordable, versatile, and offering high-performance features for motion control in machinery like robotics and conveyors. Key Features and Description: Performance: Utilizes IGBT PWM sine-wave current control for precise motor operation. Input Voltage: Designed for single-phase 200~240V AC, 50/60Hz. Encoder Compatibility: Compatible with 17-bit or 23-bit absolute encoders. Control Methods: Supports 8-segment internal speed command and 16-segment internal position command. Braking: Includes a built-in 750W braking resistor, with the option to switch to an external resistor. Communication & Tuning: Supports Modbus RTU/RS-485/RS-422, automatic load inertia identification, and rigidity self-tuning. Protection: Offers extensive protection against over-voltage, under-voltage, over-current, over-speed, over-load, over-heating, and encoder failure. I/O: Typically features 4 digital inputs and 4 outputs, with pulse input frequencies up to 500 kHz. Common Models & Specs: VD2F-003SA1P: 3A output current. VD2F-010SA1P: 10A output current. VD2F-014SA1P: 14A output current. The VD2F drives are specifically designed for space-saving installations due to their compact design, making them suitable for crowded industrial cabinets. #Wecon#WeconAutomation #WeconIndia#WeconPLC #WeconVFD#WeconHMI#WeconDrive #WeconServo #WeconBDboard #BDboard #Wecon #WeconAutomation #WeconBDboard #BDboard #WeconPLC #WeconVFD #WeconHMI #IndustrialAutomation #FactoryAutomation #ControlPanel #PanelBuilding #MachineAutomation #TamilBusiness #CoimbatoreAutomation #IndianAutomation #WeconEthernetSwitch #WeconSwitch #WeconSW05E #WeconHMI #WeconPLC #WeconVFD #WeconServo #WeconDrive #WeconControl #adhiraautomation #authorized delar for wecon products. wecon dealer in coimbatore wecon dealer in hosur wecon dealer in tirupur wecon dealers in coimbatore wecon dealers in hosur wecon dealers in tirupur WECON IoT solutions are a comprehensive suite of Industrial Internet of Things (IIoT) hardware and software designed to provide remote monitoring, data collection, and control for industrial automation. The ecosystem is built around three core components: V-BOX (IIoT Gateway): An industrial intelligent gateway that connects PLCs, sensors, and other field devices to the cloud. It supports over 300 industrial protocols (such as Modbus, EtherCAT, and Siemens/Omron/Delta protocols) and transmits data via Ethernet, Wi-Fi, or 4G. ig Series (IoT HMI): A new generation of Human-Machine Interfaces that combine traditional touch-screen control with built-in IoT capabilities. They allow for remote screen access, cloud data recording, and firmware upgrades directly through the cloud. V-NET (Cloud Platform): A centralized management platform where users can build custom dashboards (Cloud SCADA), manage device alarms, and perform remote debugging using tools like WVPN without traveling to the physical site. Key Features & Capabilities Remote Maintenance: Engineers can remotely update PLC programs or HMI configurations through a secure 'pass-through' connection. Real-Time Alerts: Critical alarm data is pushed immediately via email, mobile app notifications, or even messaging services like WeChat to ensure rapid response to failures. Edge Computing: Devices like the V-BOX support Lua scripting, allowing for local data processing and custom protocol conversion before sending information to the cloud. Third-Party Integration: The system can sync data with external platforms like AWS IoT, Google Cloud, and Microsoft Azure, or integrate with enterprise systems like MES and ERP. Common Applications Wecon IoT products are widely used for 'unattended' operations in industries such as: Smart Water Affairs: Monitoring flow, pressure, and pump status in remote water treatment plants. Smart Factories: Real-time production tracking and predictive maintenance. Energy Management: Monitoring power distribution and optimizing energy usage. Would you like to see a comparison of the different V-BOX models (E, H, or R series) or a guide on how to set up the V-NET cloud? wecon dealer in coimbatore wecon dealer in hosur wecon dealer in tirupur wecon dealers in coimbatore wecon dealers in hosur wecon dealers in tirupur The WECON VD2F series consists of compact, pulse-type servo drives designed for general-purpose industrial positioning applications. They are part of the VD2 SA series of servo drives, known for being affordable, versatile, and offering high-performance features for motion control in machinery like robotics and conveyors. Key Features and Description: Performance: Utilizes IGBT PWM sine-wave current control for precise motor operation. Input Voltage: Designed for single-phase 200~240V AC, 50/60Hz. Encoder Compatibility: Compatible with 17-bit or 23-bit absolute encoders. Control Methods: Supports 8-segment internal speed command and 16-segment internal position command. Braking: Includes a built-in 750W braking resistor, with the option to switch to an external resistor. Communication & Tuning: Supports Modbus RTU/RS-485/RS-422, automatic load inertia identification, and rigidity self-tuning. Protection: Offers extensive protection against over-voltage, under-voltage, over-current, over-speed, over-load, over-heating, and encoder failure. I/O: Typically features 4 digital inputs and 4 outputs, with pulse input frequencies up to 500 kHz. Common Models & Specs: VD2F-003SA1P: 3A output current. VD2F-010SA1P: 10A output current. VD2F-014SA1P: 14A output current. The VD2F drives are specifically designed for space-saving installations due to their compact design, making them suitable for crowded industrial cabinets. #Wecon#WeconAutomation #WeconIndia#WeconPLC #WeconVFD#WeconHMI#WeconDrive #WeconServo #WeconBDboard #BDboard #Wecon #WeconAutomation #WeconBDboard #BDboard #WeconPLC #WeconVFD #WeconHMI #IndustrialAutomation #FactoryAutomation #ControlPanel #PanelBuilding #MachineAutomation #TamilBusiness #CoimbatoreAutomation #IndianAutomation #WeconEthernetSwitch #WeconSwitch #WeconSW05E #WeconHMI #WeconPLC #WeconVFD #WeconServo #WeconDrive #WeconControl #adhiraautomation #authorized delar for wecon products. An HMI (Human-Machine Interface) is a user interface or dashboard that connects a person to a machine, system, or device. While technically applicable to any screen (like a smartphone or an ATM), the term is most commonly used in industrial automation to describe the interaction between an operator and a control system. Inductive Automation Core Functions The primary goal of an HMI is to translate complex machine data into actionable information. AVEVA Monitoring: Visualises real-time data such as temperature, pressure, and production speed via graphs and charts. Control: Allows operators to input commands, adjust setpoints, or start/stop equipment through touchscreens or buttons. Alarm Management: Displays visual and auditory alerts if parameters deviate from safe ranges, enabling quick response to issues. Data Logging: Records historical data for trend analysis, troubleshooting, and predictive maintenance. Inductive Automation Human Machine Interface (HMIs) in Industrial Automation What is an HMI? Common Types of HMI Touchscreen Panels: The most common form, often integrated directly into industrial equipment. HMI + PLC Combo: A single hardware unit that combines the display with the Programmable Logic Controller (PLC), reducing wiring and space. Industrial PCs (Panel PCs): Powerful computers running Windows or Linux that can handle complex SCADA or MES applications. Web-Based/Mobile HMI: Allows remote access through browsers or mobile apps, enabling monitoring from any location. Headless HMI: Units without a built-in screen that output video to an external monitor or mobile device. Inductive Automation HMI vs. SCADA While often used interchangeably, they serve different roles in an industrial network: HMI is typically localized to a specific machine or area for direct operator interaction. SCADA (Supervisory Control and Data Acquisition) is a larger system that collects and analyzes data from multiple HMIs and devices across a whole plant or multiple sites. Inductive Automation Key Benefits Efficiency: Centralizes control, reducing the need for operators to manually check mechanical gauges. Safety: Allows operators to control machines from a distance and provides instant alerts for critical failures. Reduced Downtime: Predictive alerts help identify mechanical problems before they lead to a full breakdown. Inductive Automation Are you looking for information on a specific HMI brand (like Siemens WinCC or Allen-Bradley FactoryTalk), or do you need help with HMI design principles? AI can make mistakes, so double-check responses #HMI #HumanMachineInterface #TIAPortal #Siemens #PLC #IndustrialAutomation #AutomationEngineering #SCADA #ControlSystems #IndustrialIoT